2025-06-13

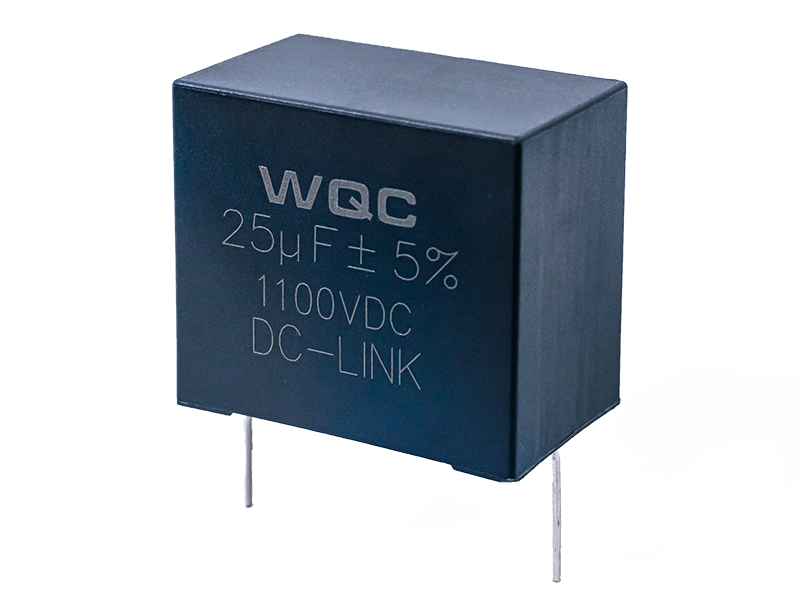

High-frequency metal-film capacitors, as critical components in electronic devices, play an irreplaceable role in high-frequency circuits thanks to their excellent electrical performance and stability. This article provides a detailed analysis of high-frequency metal-film capacitors from three perspectives: their fundamental characteristics, application fields, and advantages.

I. Fundamental Characteristics of High-Frequency Metal-Film Capacitors

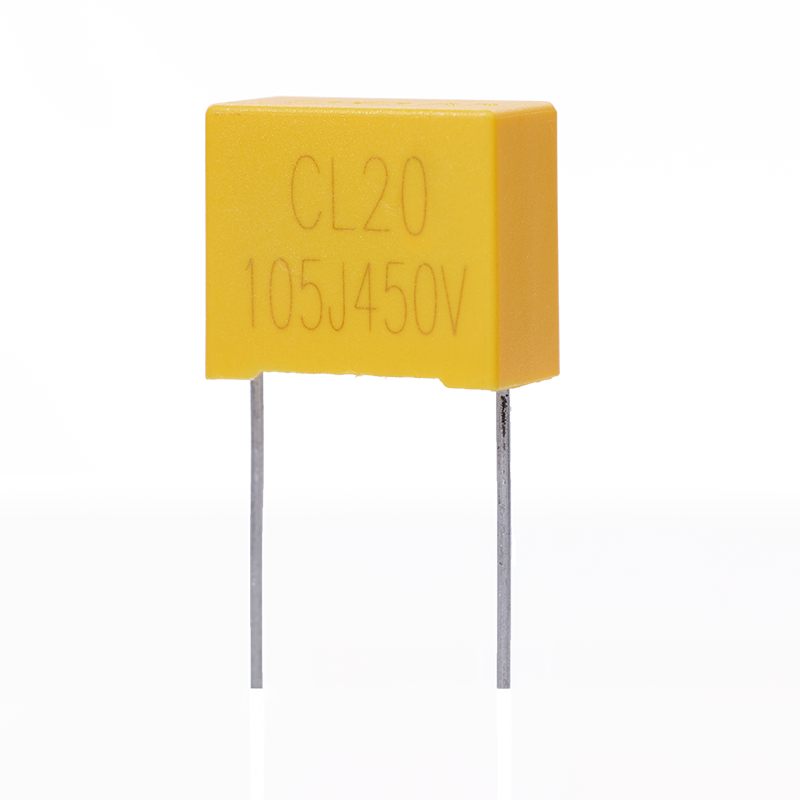

High-frequency metal-film capacitors are manufactured using vacuum evaporation technology, in which an ultra-thin metal layer—typically made of zinc or aluminum-zinc alloy—is directly deposited onto an extremely thin plastic dielectric film to serve as the electrode, rather than relying on separate metal foils. This unique structure endows the capacitor with exceptionally high self-healing capability. When defects occur in the dielectric film or when localized dielectric breakdown is triggered by overvoltage surges, the metal coating surrounding the breakdown point rapidly evaporates and oxidizes under the high temperature and electric arc generated at the moment of breakdown, forming an insulating isolation zone. As a result, the short-circuit location is automatically eliminated, allowing the capacitor to return to an almost pristine insulating state and continue functioning normally. Moreover, high-frequency metal-film capacitors exhibit low losses, excellent frequency response, a small temperature coefficient, and high dielectric strength.

II. Application Fields of High-Frequency Metal-Film Capacitors

High-Frequency Circuits: High-frequency metal-film capacitors excel in high-frequency circuits, such as resonant, matching, and filtering applications. Their outstanding frequency characteristics enable them to perform exceptionally well in these applications.

Precision component in high-frequency metal film capacitor electronic circuits

2025-05-29

In the rapid wave of modern electronic technology development, high-frequency metal-film capacitors—playing an indispensable role in numerous fields—are emerging as a crucial electronic component. At the heart of these high-frequency metal-film capacitors lies the use of metal films as electrode materials. These metal films typically have extremely thin thicknesses, a characteristic that endows the capacitors with unique performance attributes. From an external perspective, they may appear as merely small components; yet internally, the metal films are meticulously fabricated and assembled. During manufacturing, advanced coating technologies are employed to uniformly deposit metal onto dielectric substrates, forming the electrodes, which are then encapsulated. In terms of performance, high-frequency metal-film capacitors exhibit outstanding high-frequency characteristics. In high-frequency circuits, signal transmission and processing demand that capacitors can charge and discharge rapidly while minimizing signal loss. Thanks to their inherent structural and material advantages, high-frequency metal-film capacitors can effectively meet these requirements. For instance, in communication equipment—from mobile base stations to satellite communication devices—processing high-frequency signals is critical. High-frequency metal-film capacitors can efficiently filter out noise from high-frequency signals, ensuring signal purity and thereby enhancing the stability and reliability of communication. Moreover, these capacitors demonstrate excellent stability under varying conditions, such as temperature and voltage fluctuations.

High-frequency metal film capacitors are key components in high-frequency circuits.

2025-05-14

High-frequency metal film capacitors are electronic components that play a critical role in high-frequency circuits. Thanks to their unique structure and performance characteristics, they are widely used in numerous fields such as telecommunications, computing, and automotive electronics.

I. Structure and Principle

High-frequency metal film capacitors primarily consist of three main parts: metallized film electrodes, a dielectric layer, and an outer casing. The metallized film electrodes are formed by depositing a metallic film onto a dielectric substrate. This structure ensures that the capacitor’s electrodes are tightly bonded to the dielectric material. The dielectric layer typically uses materials such as polyester film or polyimide film, which serve to insulate the two electrodes from each other and ensure the proper functioning of the capacitor. When a voltage is applied across the capacitor’s two plates, an electric field is established within the dielectric material, causing charges to accumulate between the two electrodes and thus enabling the capacitor to perform its function.

II. Performance Characteristics

(1) Excellent High-Frequency Performance

High-frequency metal film capacitors excel in high-frequency signal processing. They maintain low equivalent series resistance (ESR) and low equivalent series inductance (ESL) in high-frequency circuits, effectively filtering out noise and reducing signal distortion, thereby enhancing the signal transmission speed of the circuit. As a result, these capacitors have become the preferred component for high-frequency circuits and are widely used in high-frequency applications such as communication equipment, automotive electronics, and industrial control systems.

(2) Good Stability

The thin...

Y2 Safety Film Capacitor: The Guardian of Safety in Electronic Circuits

2025-04-29

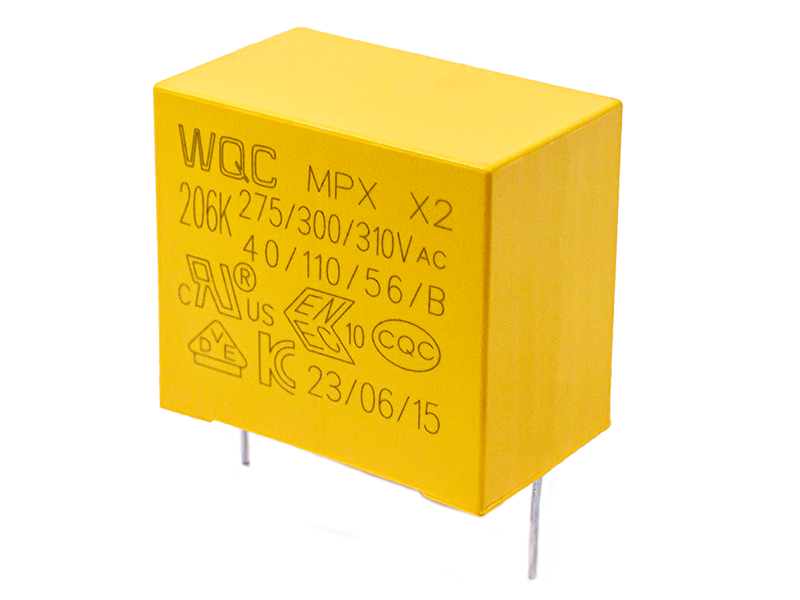

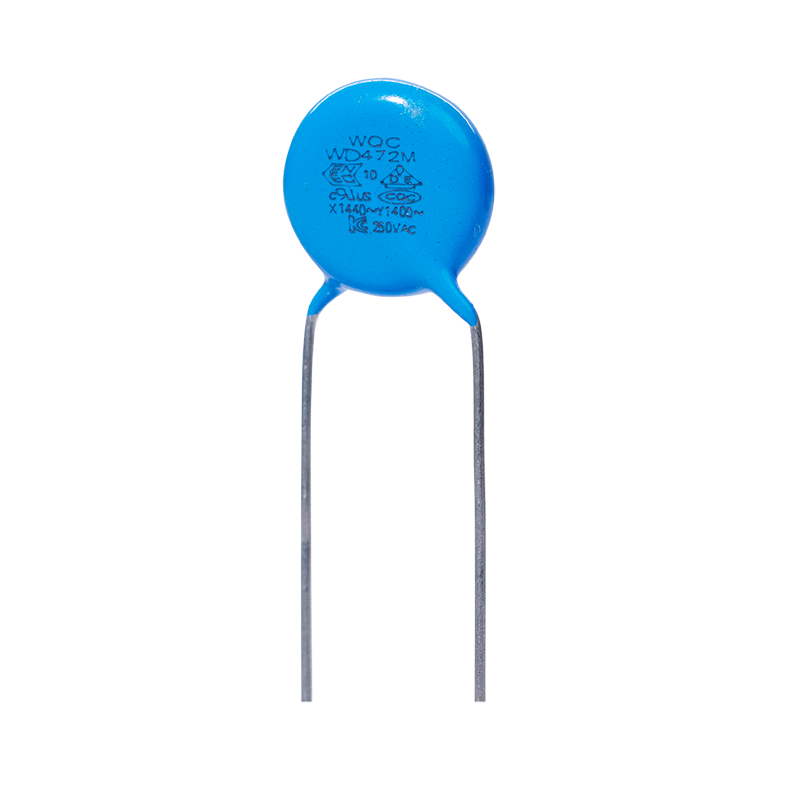

In the field of electronic circuits, Y2 safety-rated film capacitors, with their unique performance characteristics, have become critical components that ensure the safe and stable operation of equipment, playing an important role across multiple industries. The Y2 safety-rated film capacitor is a safety protection component whose core function is to suppress electromagnetic interference and protect equipment from high-voltage surges. Typically, it is constructed by winding metallized polypropylene film and then encapsulating it with epoxy resin. This structural design not only provides the capacitor with stable electrical performance but also offers excellent mechanical protection. Its internal structure is designed to be non-inductive, effectively eliminating parasitic inductance at high frequencies and thus ensuring reliable operation even in high-frequency circuits. The electrode material is primarily composed of zinc and aluminum, offering good self-healing properties; after localized breakdown, the capacitor can quickly restore its insulation, thereby extending its service life. In terms of performance parameters, the Y2 safety-rated film capacitor demonstrates outstanding capabilities. Its rated voltage typically ranges from 250VAC to 300VAC, and its test voltage can reach over 2600VAC, enabling it to withstand high operating voltages and ensuring stable operation in complex circuit environments. The capacitance range is concentrated between 100pF and 4700pF, meeting the diverse capacitance requirements of different circuits. Moreover, its temperature coefficient is highly stable—within the temperature range from -40℃ to +110℃, the capacitance variation does not exceed ±10%, allowing it to maintain reliable performance under a wide variety of operating conditions.

Y2 safety-rated film capacitors ensure the safety of electronic devices.

2025-04-14

In modern electronic devices, capacitors—being crucial passive components—perform a variety of functions, including energy storage, filtering, and coupling. Among them, Y2 safety film capacitors, as a type of safety capacitor, play an indispensable role in electronic equipment thanks to their unique safety performance and reliability.

I. Definition and Characteristics of Y2 Safety Film Capacitors

The Y2 safety film capacitor is one of the Y-series safety capacitors, primarily used to suppress electromagnetic interference from power supplies and ensure the normal operation and safety of electronic devices. It uses a thin film as its dielectric material, offering high insulation performance, strong resistance to surge currents, and a long service life. Moreover, Y2 safety film capacitors have passed numerous international safety certification standards, such as CQC, VDE, ENEC, IEC-CB, UL, and CUL, further attesting to their outstanding safety credentials.

II. Working Principle of Y2 Safety Film Capacitors

The working principle of the Y2 safety film capacitor is based on the fundamental property of capacitors: their ability to store and release electric charge. In electronic devices, the Y2 safety film capacitor is connected between the power line and the ground, forming a low-impedance path that effectively suppresses electromagnetic interference from the power supply. When high-frequency noise or surge voltages occur on the power line, the Y2 safety film

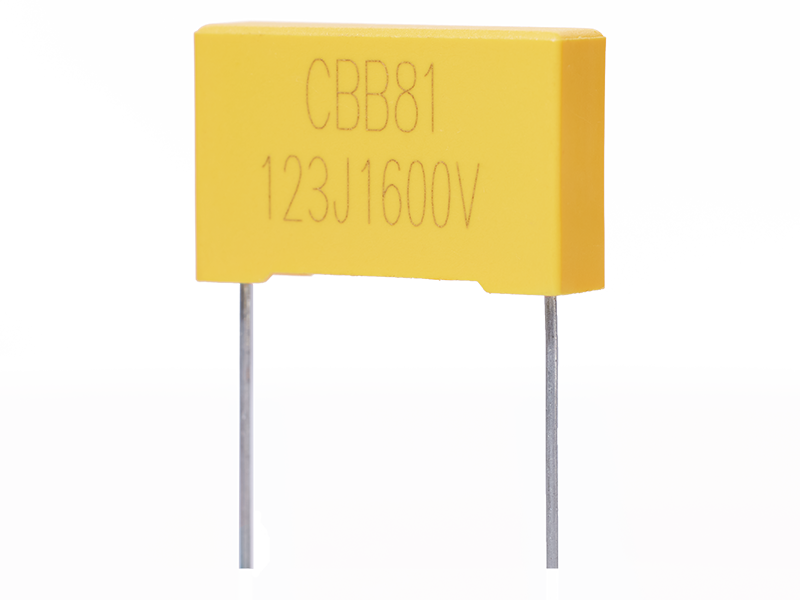

Dongguan Safety Capacitor: The Guardian of Safety in Electronic Circuits

2025-04-01

Dongguan safety-rated capacitors, as a special type of capacitor, play a crucial role in electronic circuit design. They not only perform the basic functions of conventional capacitors—such as storing electrical energy, filtering, and coupling—but more importantly, they ensure that, in the event of capacitor failure, no electric shock accidents will occur, thereby safeguarding personal safety.

I. Definition of Safety-Rated Capacitors

Dongguan safety-rated capacitors are capacitors that, upon failure, will not cause electric shocks and pose no threat to personal safety. In electronic circuits—especially those requiring high safety and reliability, such as power supply circuits and communication circuits—they play an irreplaceable role.

II. Characteristics of Safety-Rated Capacitors

High Safety: Safety-rated capacitors undergo rigorous safety testing and certification, complying with relevant safety standards and regulations. After failure, these capacitors enter an open-circuit state, preventing the flow of large currents and thus avoiding electric shock accidents.

High Voltage and High Temperature Resistance: Safety-rated capacitors typically feature high voltage ratings and excellent temperature resistance, enabling them to operate stably even under harsh environmental conditions.

Long Lifespan: Thanks to the use of high-quality materials and advanced manufacturing processes, safety-rated capacitors generally have a long service life, reducing the frequency of maintenance and replacement.

Self-Healing Properties: Certain safety-rated capacitors (