-

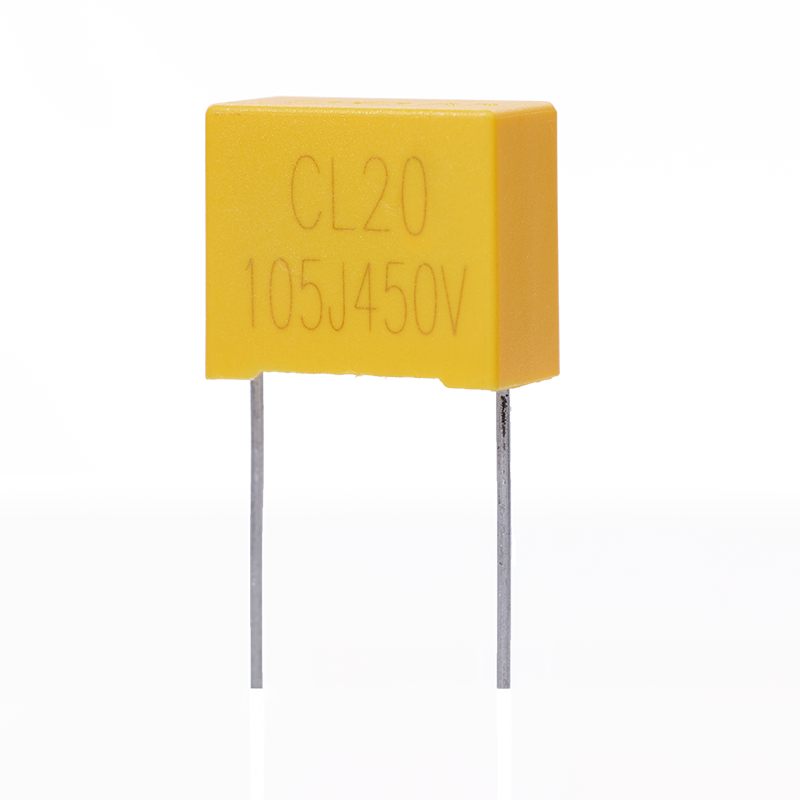

X1

Capacity and voltage range from low to high, widely distributed. Can be applied to lighting and consumer electronics.

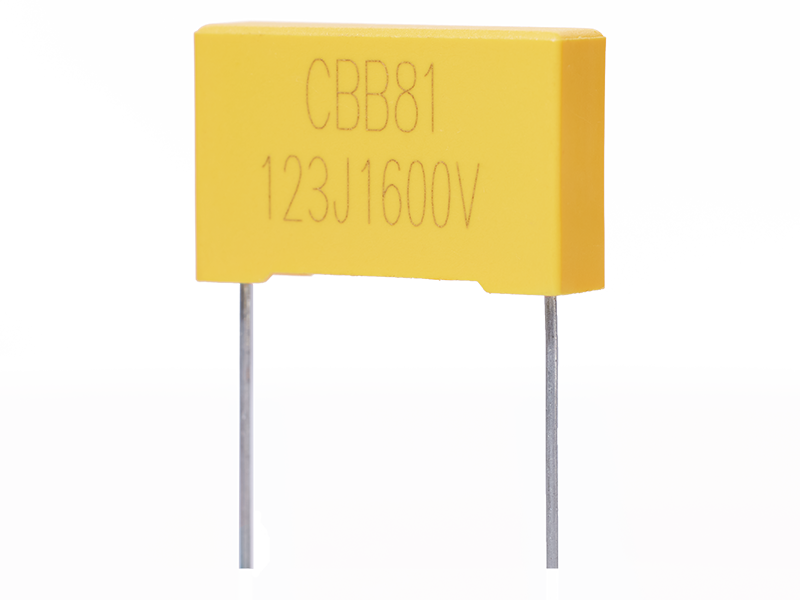

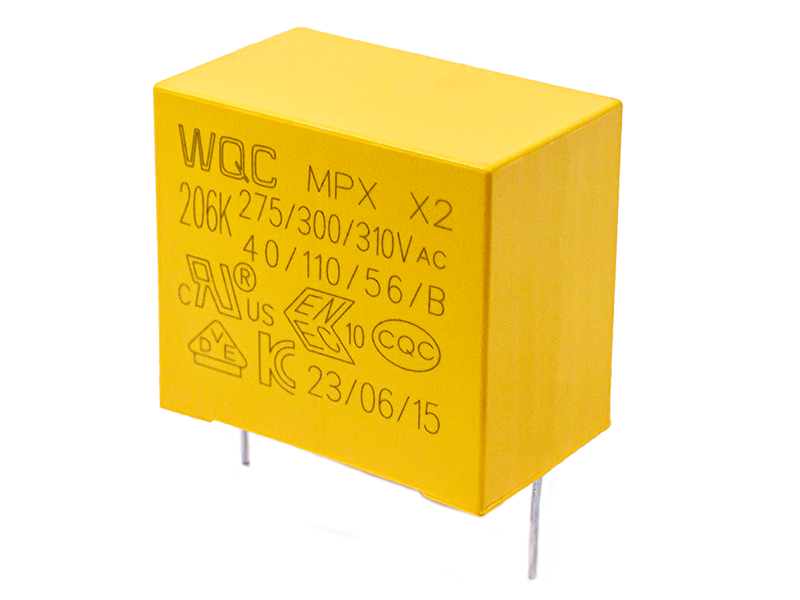

X2

Capacity and voltage range from low to high, widely distributed. Can be applied to lighting and consumer electronics.

Y1

Capacity and voltage range from low to high, widely distributed. Can be applied to lighting and consumer electronics.

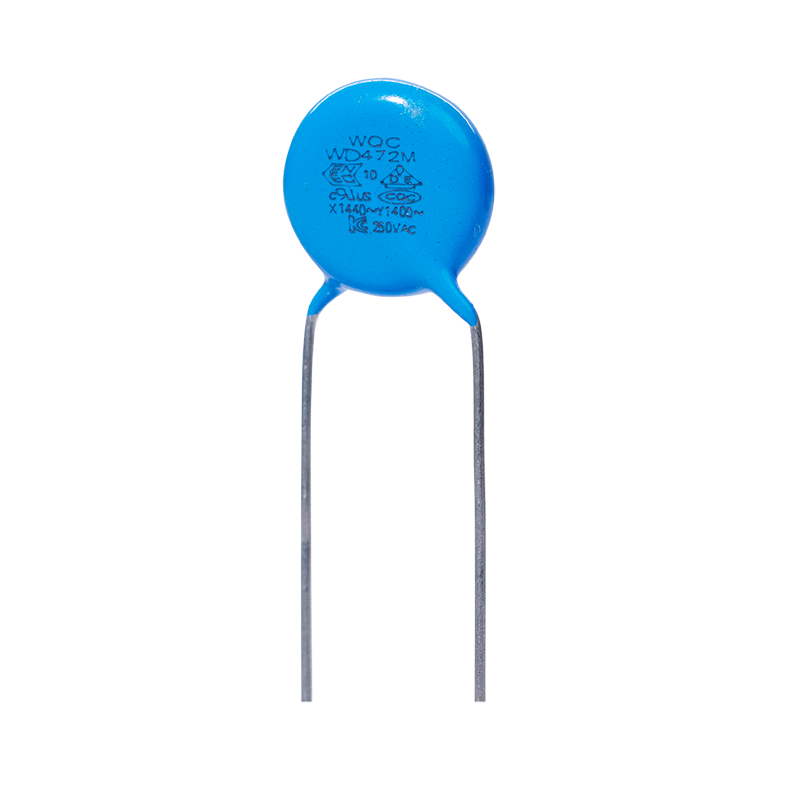

Y2

Capacity and voltage range from low to high, widely distributed. Can be applied to lighting and consumer electronics.

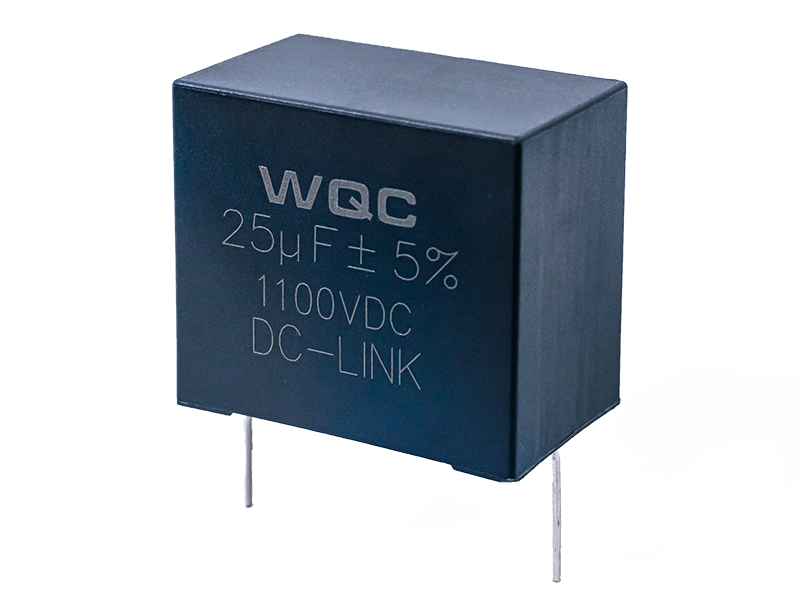

MEC Metal Film Box

Supercapacitors are also known as electric double-layer capacitors.

2024-01-05

Properties of Film Materials Used in Thin-Film Capacitors

2024-01-05

2024-01-05

2024-01-05

Overview of the structure and characteristics of film capacitors

2024-01-05

Standardization of film capacitors

2024-01-05

Service Hotline:

Contact

Phone: +86 13826981362

Tel:+86 076988956188

E-mail: wqc001@weiqingchina.com.cn

Address: Weiqing Electronics Co., Ltd., Floor 1, Building 12, No.7, Science and Technology 10th Road, Songshan Lake High-tech Development Zone, Songshan Lake Administrative Committee, Dongguan City, Guangdong Province

Mobile Website

Scan Consultation