Self-healing of metallized film capacitors

Release time:

2024-01-05 17:26

Source:

Metallized film capacitors have self-healing properties that are not available in film/foil configurations. When a sufficient voltage is applied, point defect shorts between the metallized electrodes can evaporate due to the high arc temperature because the dielectric plastic material at the breakdown point and the metallized electrodes around the breakdown point are both very thin (about 0.02 to 0.05 microns). The point defect cause of the short circuit is burned, and the resulting steam pressure also blows the arc away. This process can be completed in less than 10 μs, usually without interrupting the useful operation of the affected capacitor. This self-healing property allows the use of single-layer windings of metallized film without any additional defect protection, thereby reducing the amount of physical space required to achieve a given performance specification. In other words, the so-called volumetric efficiency of the capacitor is improved. The self-healing ability of the metallized film is used many times during the manufacture of metallized film capacitors. Generally, after the metallized film has been cut to a desired width, any resulting defects can be burned (repaired) by applying a suitable voltage before winding. The same method is also used after contact surface metallization (schopage) to remove any defects in the capacitor caused by the second metallization process. Metallized pinholes caused by self-healing arcs can very slightly reduce the capacitance of the capacitor. However, the magnitude of this reduction is small; even if there are thousands of defects to be burned out, this reduction is usually much less than 1% of the total capacitance of the capacitor. For large film capacitors with very high stability and long life standards, such as buffer capacitors, special fault isolation patterns can be used for metallization. In the picture on the right, this metallization forming a T-shaped pattern is shown. Each of these T-shaped patterns creates an intentionally narrowed cross-section in the conductive metallization layer. These limits work like a miniature fuse, so if a point defect short circuit occurs between the electrodes, the high current of the short circuit will only burn the fuse around the fault. Thus, the affected part is disconnected and isolated in a controlled manner without any explosion around the larger short-circuit arc. Therefore, the affected area is limited, the fault is mitigated and controlled, and the internal damage to the capacitor is significantly reduced. In the field installation of power distribution equipment, the fault tolerance of the capacitor bank is usually improved by connecting multiple capacitors in parallel. Each capacitor is protected by an internal or external fuse. If a single capacitor is internally short-circuited, the resulting fault current (enhanced by the capacitive discharge of adjacent capacitors) will blow the fuse, thereby isolating the faulty capacitor from the rest of the equipment. This technique is similar to the T-metallization technique described above, but operates on a much larger physical scale. More complex series and parallel arrangements of capacitor banks are also used to allow continuity of service, albeit in the event of a single capacitor failure of this larger scale.

Previous Page

Related News

Increase the internal structure of the rated voltage

The voltage ratings for different film materials depend on factors such as film thickness, material quality (free of physical defects and chemical impurities), ambient temperature and operating frequency, and the safety margin for breakdown voltage (dielectric strength). In general, however, the rated voltage of a film capacitor depends primarily on the thickness of the plastic film. For example, with the minimum usable film thickness of a polyester film capacitor (about 0.7 μm), a capacitor rated at 400V DC can be produced. If a higher voltage is required, a thicker plastic film is usually used

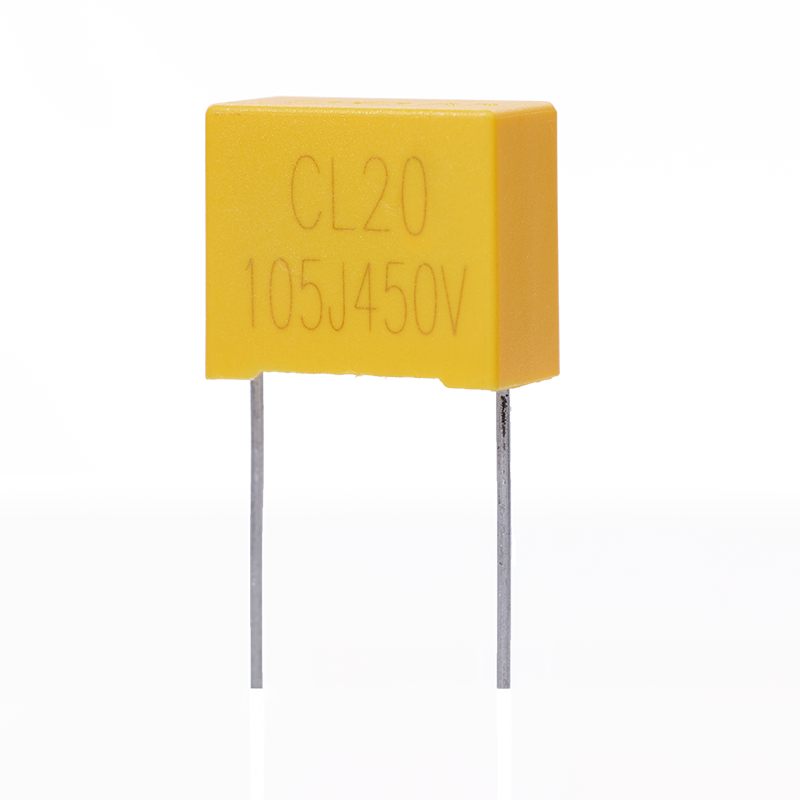

Self-healing of metallized film capacitors

Metallized film capacitors have self-healing properties that are not available in film/foil configurations. When a sufficient voltage is applied, point defect shorts between the metallized electrodes can evaporate due to the high arc temperature because the dielectric plastic material at the breakdown point and the metallized electrodes around the breakdown point are both very thin (about 0.02 to 0.05 microns). The point defect cause of the short circuit is burned, and the resulting steam pressure also blows the arc away. This process can be completed in less than 10 μs

Brief Analysis of Fault Treatment of Capacitor

When the fuse of the capacitor is blown, it shall be reported to the dispatcher, and the circuit breaker of the capacitor shall be opened after obtaining the approval. Cut off the power supply to discharge it, and conduct external inspection first, such as whether there are flashover marks on the outside of the casing, whether the shell is deformed, whether there is oil leakage and whether there is short circuit in the grounding device, etc., and measure the insulation resistance value between poles and poles to ground, and check whether the capacitor bank wiring is complete and firm, and whether there is phase loss

Detection method of fixed capacitor

1. Detect the small capacitance below 10pF: because the fixed capacitor capacity below 10pF is too small, using a multimeter to measure, can only qualitatively check whether there is leakage, internal short circuit or breakdown. When measuring, a multimeter R× 10k block can be selected, and two pens can be used to connect the two pins of the capacitor arbitrarily, and the resistance value should be infinite. If the measured resistance (pointer swing to the right) is zero, then the capacitor leakage damage or internal breakdown.

Supercapacitors are also known as electric double-layer capacitors.

Supercapacitor, also known as electric double layer capacitor and electrochemical capacitor, is a new type of electrochemical energy storage device with electrochemical performance between traditional capacitors and batteries. It mainly includes four parts: electrode, electrolyte, current collector and separator. It mainly stores energy through the electric double layer capacitance and the Faraday quasi-capacitance generated by the redox reaction. Generally speaking, the energy storage of supercapacitors is reversible, so it can be used to solve problems such as battery memory. At present, the application range of supercapacitors is very wide.