Capacitor manufacturing process

Release time:

2024-03-15 10:31

Source:

About Capacitor Manufacturing Process-Professional Analysis and Sales Expression of Safety Capacitor

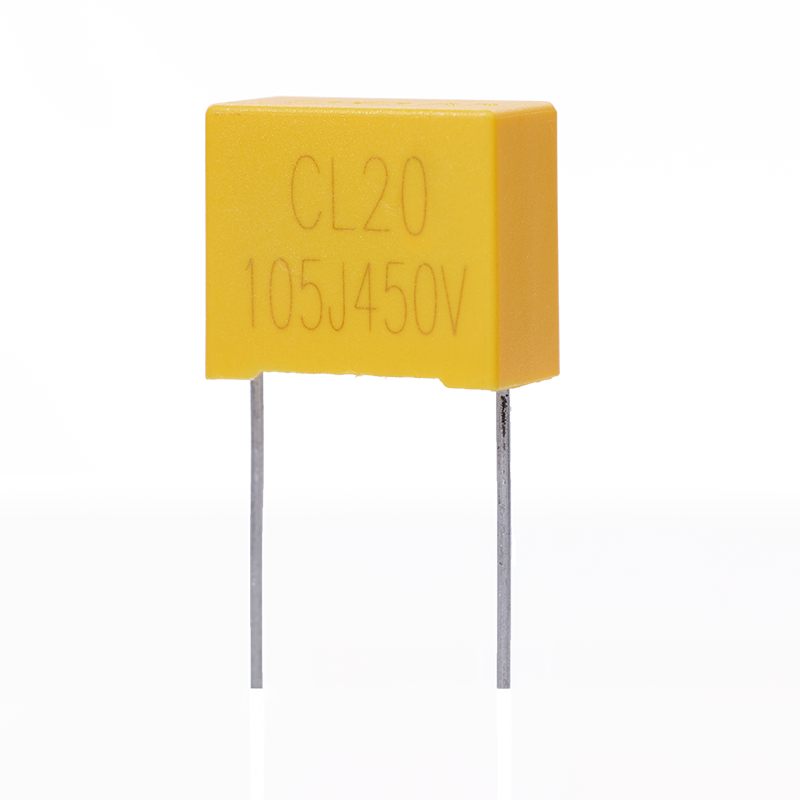

Dear customers, hello! In the electronics industry, the capacitor is an important energy storage element, and its manufacturing process is directly related to the performance and quality of the product. Today, I will give you a detailed introduction of the safety capacitor manufacturing process, with you to appreciate its excellent quality and unique value.

1. safety capacitor overview

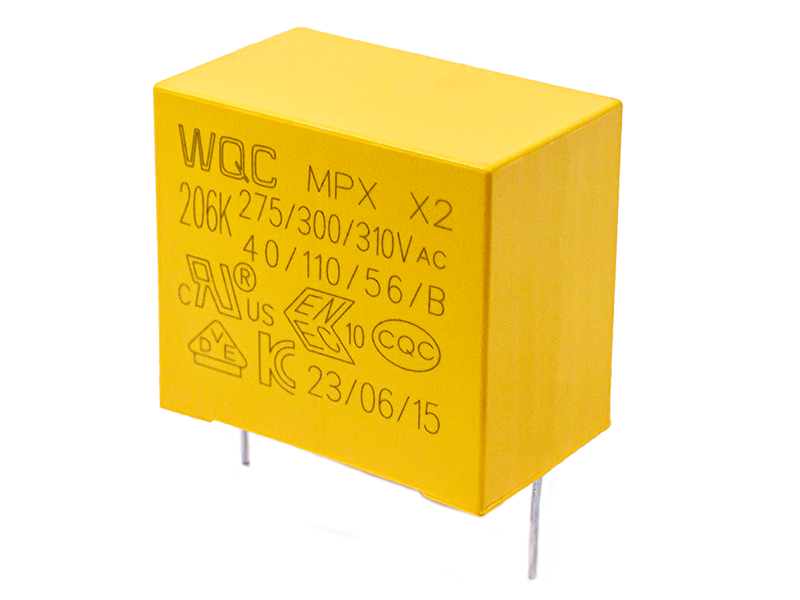

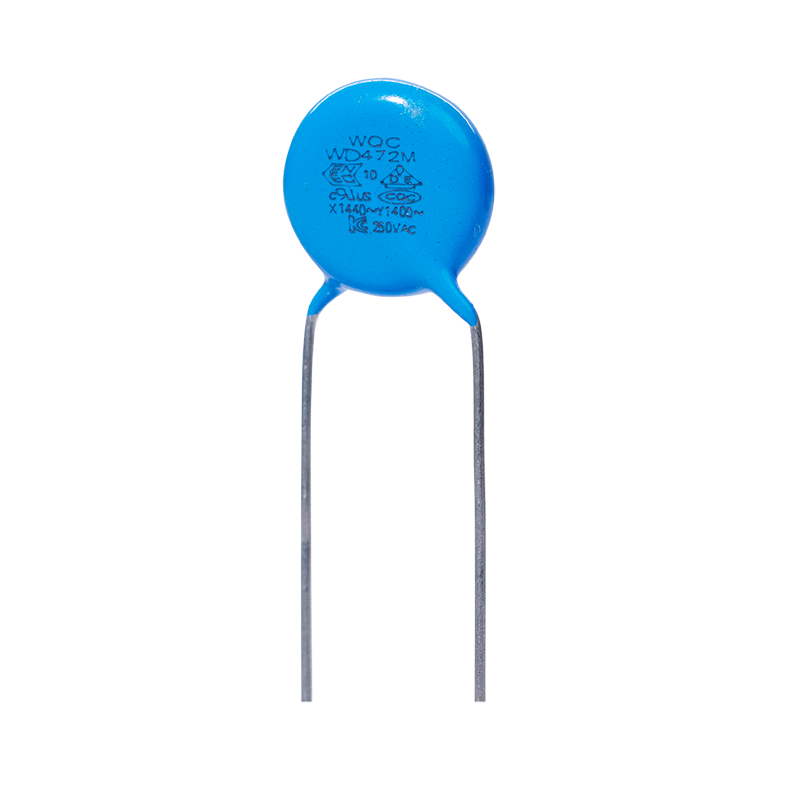

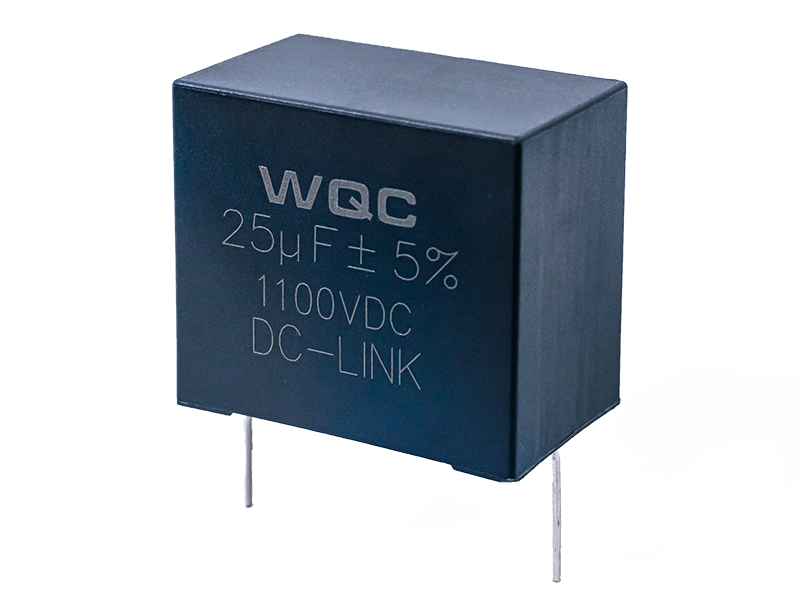

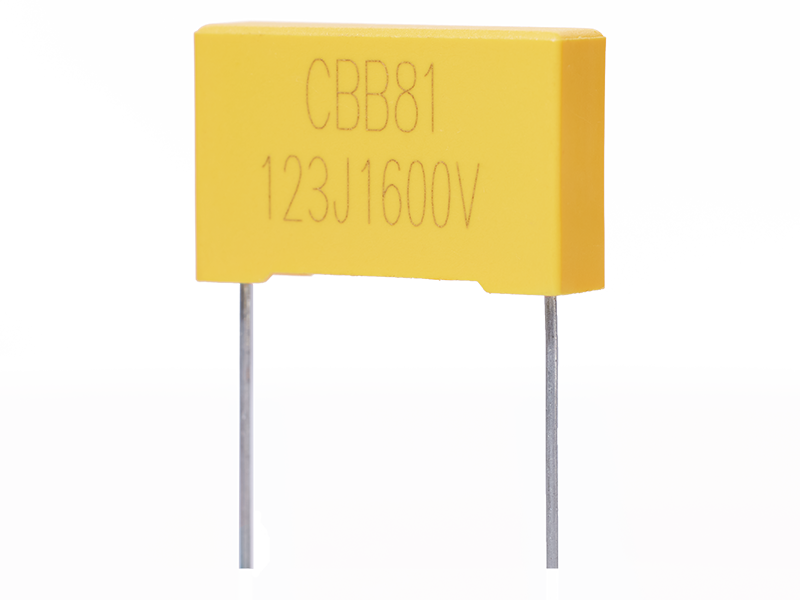

Safety capacitor, as the name suggests, is a kind of capacitor products that pay attention to safety performance. In electronic equipment, it can effectively filter out the ripple, purify the power supply, and ensure the stable operation of the circuit. Its unique design and manufacturing process make it show excellent performance under high voltage and high current environment.

Introduction of 2. Capacitor Manufacturing Process

1. Material preparation: The core of the capacitor lies in the dielectric material. The safety capacitor usually uses high-quality metal oxide, polypropylene and other dielectric materials to ensure the stability and durability of the product.

2. Evaporation process: the prepared dielectric material is formed into a thin film on the insulating substrate by evaporation technology to form the electrode of the capacitor.

3. Corrosion treatment: chemical etching or laser etching technology is used to form a specific pattern on the electrode to ensure the precise performance of the capacitor.

4. Assembly and packaging: the processed electrodes and media are assembled together, the leads are connected by welding or conductive adhesive, and finally packaged to protect the internal structure from the external environment.

5. Safety performance testing: Strict safety performance testing is carried out on the made capacitors to ensure that they can operate stably under harsh environments such as high pressure and high temperature.

Advantages of 3. safety capacitors

1. High performance: The safety capacitor adopts advanced manufacturing technology, has the characteristics of low impedance, high withstand voltage, and high current, which can meet the high performance requirements of electronic equipment.

2. Strong safety: After strict safety performance testing, the safety capacitor has excellent explosion-proof and anti-leakage performance to ensure the safe operation of electronic equipment.

3. Good stability: Made of high-quality materials, the safety capacitor has long-term stable performance to ensure the stable operation of electronic equipment.

4. Wide range of application: safety capacitors are suitable for various electronic devices, such as power supplies, communication equipment, computers, etc., and have a wide range of applications.

4. Sales Expression

Dear customers, our safety capacitors adopt advanced manufacturing technology, select high-quality materials, and undergo strict safety performance tests. They have the advantages of high performance, strong safety, and good stability. In electronic equipment, it can effectively improve the stability of the circuit, filter out ripples, and purify the power supply. Our safety capacitors are widely used in power supply, communication equipment, computers and other fields, is your reliable quality products. We promise to provide perfect after-sales service to ensure your use worry-free.

5. epilogue

In today's rapid development of the electronics industry, as an important electronic component, the manufacturing process and quality of safety capacitors are very important. Our safety capacitor with its excellent performance and stable quality performance, has won the trust and support of our customers. We look forward to establishing a long-term and stable cooperative relationship with you and jointly creating a better future!

Related News

Increase the internal structure of the rated voltage

The voltage ratings for different film materials depend on factors such as film thickness, material quality (free of physical defects and chemical impurities), ambient temperature and operating frequency, and the safety margin for breakdown voltage (dielectric strength). In general, however, the rated voltage of a film capacitor depends primarily on the thickness of the plastic film. For example, with the minimum usable film thickness of a polyester film capacitor (about 0.7 μm), a capacitor rated at 400V DC can be produced. If a higher voltage is required, a thicker plastic film is usually used

Self-healing of metallized film capacitors

Metallized film capacitors have self-healing properties that are not available in film/foil configurations. When a sufficient voltage is applied, point defect shorts between the metallized electrodes can evaporate due to the high arc temperature because the dielectric plastic material at the breakdown point and the metallized electrodes around the breakdown point are both very thin (about 0.02 to 0.05 microns). The point defect cause of the short circuit is burned, and the resulting steam pressure also blows the arc away. This process can be completed in less than 10 μs

Brief Analysis of Fault Treatment of Capacitor

When the fuse of the capacitor is blown, it shall be reported to the dispatcher, and the circuit breaker of the capacitor shall be opened after obtaining the approval. Cut off the power supply to discharge it, and conduct external inspection first, such as whether there are flashover marks on the outside of the casing, whether the shell is deformed, whether there is oil leakage and whether there is short circuit in the grounding device, etc., and measure the insulation resistance value between poles and poles to ground, and check whether the capacitor bank wiring is complete and firm, and whether there is phase loss

Detection method of fixed capacitor

1. Detect the small capacitance below 10pF: because the fixed capacitor capacity below 10pF is too small, using a multimeter to measure, can only qualitatively check whether there is leakage, internal short circuit or breakdown. When measuring, a multimeter R× 10k block can be selected, and two pens can be used to connect the two pins of the capacitor arbitrarily, and the resistance value should be infinite. If the measured resistance (pointer swing to the right) is zero, then the capacitor leakage damage or internal breakdown.

Supercapacitors are also known as electric double-layer capacitors.

Supercapacitor, also known as electric double layer capacitor and electrochemical capacitor, is a new type of electrochemical energy storage device with electrochemical performance between traditional capacitors and batteries. It mainly includes four parts: electrode, electrolyte, current collector and separator. It mainly stores energy through the electric double layer capacitance and the Faraday quasi-capacitance generated by the redox reaction. Generally speaking, the energy storage of supercapacitors is reversible, so it can be used to solve problems such as battery memory. At present, the application range of supercapacitors is very wide.