The main difference between patch safety capacitors and conventional capacitors

Release time:

2025-11-27 09:15

Source:

In the world of electronic components, capacitors are undoubtedly a crucial element. Among the various types of capacitors, the distinction between surface-mount safety capacitors and traditional capacitors often leaves many engineers and enthusiasts puzzled. So, what exactly is a surface-mount safety capacitor? And how does it differ significantly from traditional capacitors? Today, let’s dive deep into this topic together.

What is a patch-type safety capacitor?

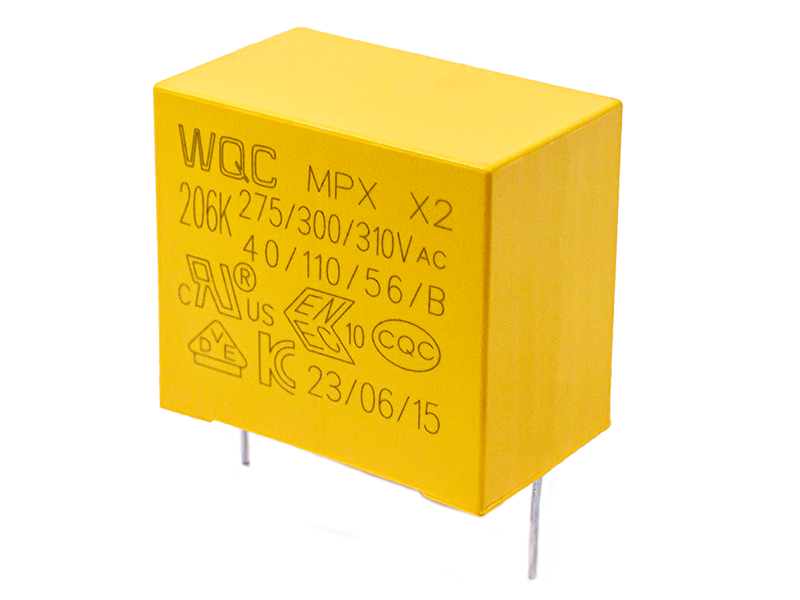

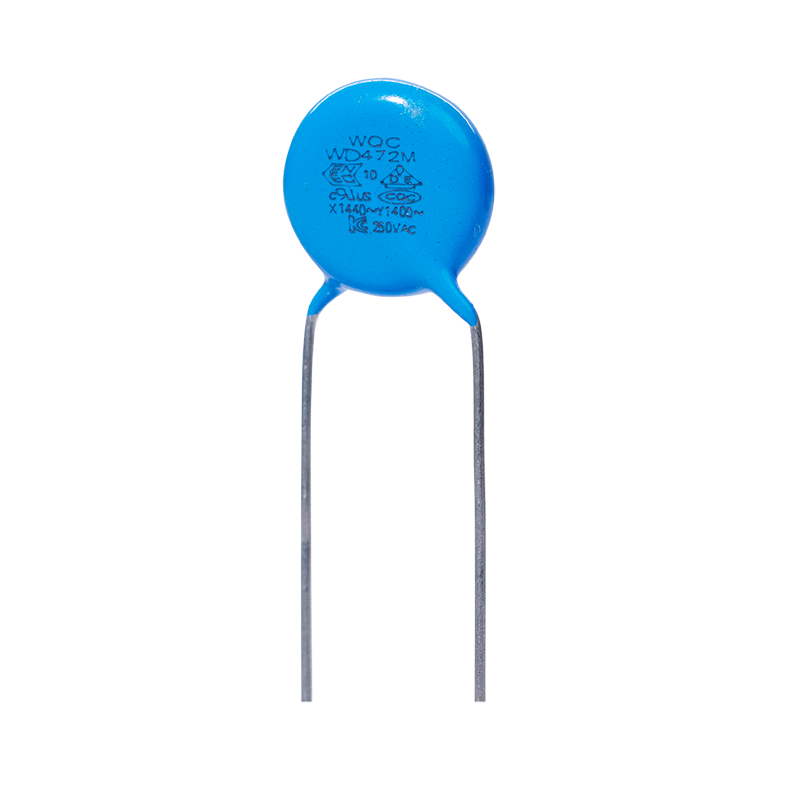

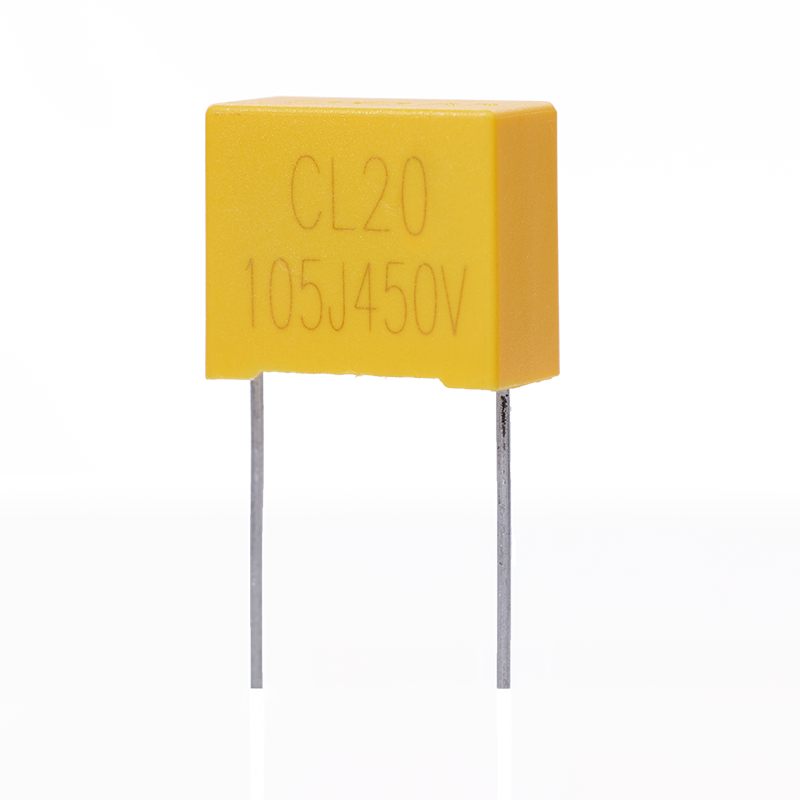

First, let’s take a look at surface-mount safety capacitors. As the name suggests, a surface-mount safety capacitor is a type of surface-mount capacitor commonly used to ensure the safety of electrical equipment. These capacitors are primarily employed in AC circuits, where they can effectively suppress electromagnetic interference (EMI) from power equipment and guarantee that the equipment will continue to operate safely even in the event of a failure.

You might ask, why is it called an “safety” capacitor? That’s because it meets stringent testing standards set by organizations such as UL and VDE, enabling it to operate safely even in high-voltage and high-temperature environments. In contrast, conventional capacitors are often used for general applications and may not have undergone such rigorous safety certifications.

The main difference between patch safety capacitors and conventional capacitors

Next, let’s analyze several key differences between surface-mount safety capacitors and traditional capacitors.

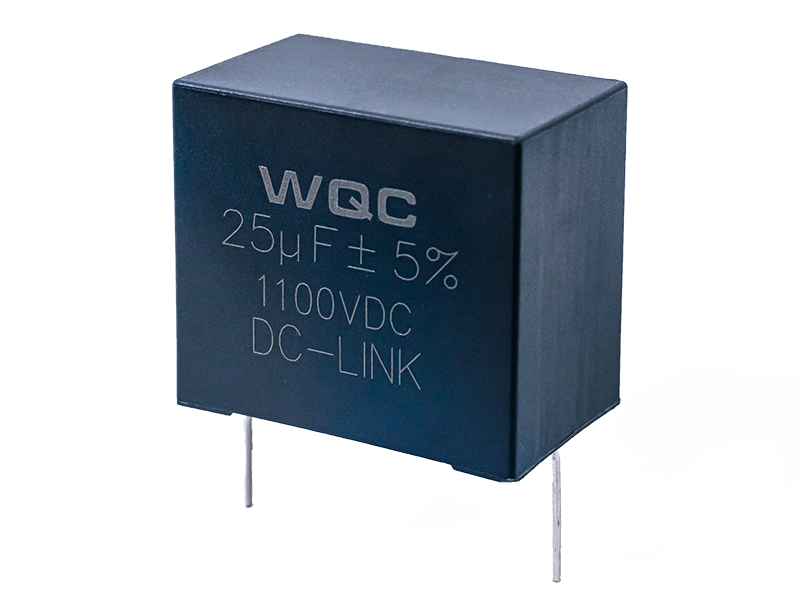

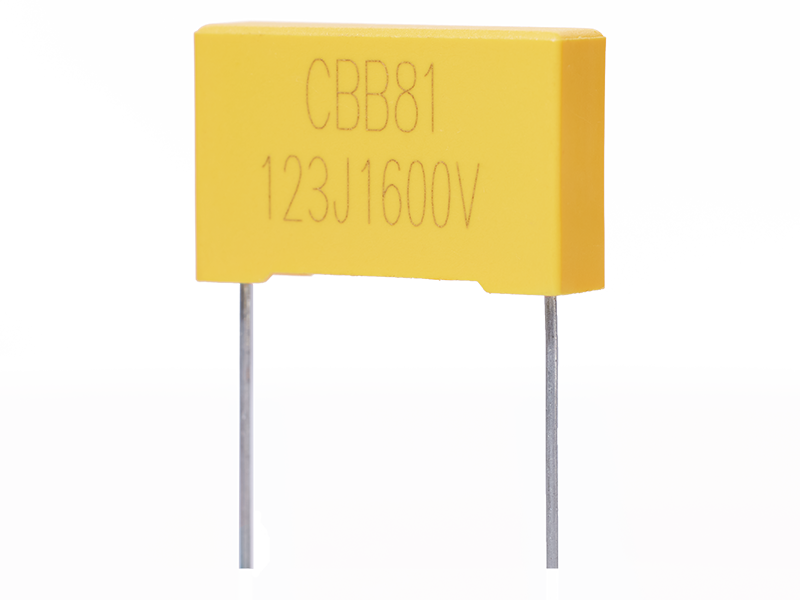

1. Dimensions and Package Type

Surface-mount safety capacitors typically come in a compact, surface-mount package, making them extremely convenient for use on circuit boards with limited space. By contrast, conventional capacitors are generally larger in size and may require more installation space. Therefore, if your design demands compactness, surface-mount safety capacitors are undoubtedly the better choice.

2. Security and Performance

As mentioned earlier, patch-type safety capacitors have undergone rigorous safety testing and can operate reliably under high-voltage and high-temperature conditions. While conventional capacitors also perform well, they may fall slightly short in terms of safety. It’s like a knife: although both can cut things, a knife that has been meticulously sharpened is clearly more reliable when it comes to safe use.

3. Application Scenarios

Patch-type safety capacitors are typically used in applications requiring high safety levels, such as home appliances and communication devices. In contrast, conventional capacitors can be found in many everyday electronic devices, like audio systems and televisions. It’s just like the difference between a sports car and a family sedan—each has its own unique purpose: one is designed for speed and performance, while the other is built for everyday practicality.

4. Price

Relatively speaking, surface-mount safety capacitors typically cost more than conventional capacitors due to their special design and rigorous testing. It’s just like when you buy a branded garment versus an ordinary one at a shopping mall—the branded item usually comes with a significantly higher price tag, but its quality and safety are also much more reliably guaranteed.

Reasons for Choosing Chip Safety Capacitors

So, why should you prioritize selecting surface-mount safety capacitors when making your capacitor selection? First, if your product involves high voltage or needs to operate in harsh environments, choosing surface-mount safety capacitors will significantly reduce the risk of failure. Second, as technology advances, an increasing number of devices are placing higher demands on electromagnetic compatibility (EMC), and surface-mount safety capacitors happen to be perfectly suited to meet these requirements.

Of course, the final choice ultimately depends on the specific application scenario and cost budget. If you’re only working with simple circuits, traditional capacitors might be sufficient; but if you’re designing devices that require high safety and high performance, surface-mount safety capacitors will be indispensable.

Summary

In summary, the differences between surface-mount safety capacitors and traditional capacitors lie in several aspects, including size, performance, safety, and application scenarios. In today’s world, where electronic devices are increasingly demanding higher levels of safety and performance, surface-mount safety capacitors have become even more crucial. Choosing the right capacitor not only enhances the stability of your device but also effectively reduces potential safety hazards.

In the selection of future electronic components, surface-mount safety capacitors will undoubtedly become the choice of an increasing number of designers.

Related News

The difference between high-frequency metal film capacitors and conventional capacitors

The Difference Between High-Frequency Metal-Film Capacitors and Traditional Capacitors In the world of electronic products, capacitors play an extremely important role. Although we may rarely pay attention to these tiny components in our daily lives, different types of capacitors excel in various application scenarios. Today, let’s talk about the differences between “high-frequency metal-film capacitors” and traditional capacitors. First, let’s clarify what a high-frequency metal-film capacitor is. Simply put, it’s a type of capacitor used for high-frequency signal processing, with a metal film serving as its dielectric material. The manufacturing process of this type of capacitor is relatively complex—but precisely because of this complexity, its performance is remarkably advanced. By contrast, traditional capacitors typically use electrolytes or ceramics as their dielectric materials. While they can still perform basic capacitance functions, they fall short when it comes to high-frequency applications. Frequency Response: The Advantage of High-Frequency Metal-Film Capacitors So why do high-frequency metal-film capacitors perform so exceptionally well in high-frequency applications? It all comes down to their frequency-response characteristics. To put it simply, when high-frequency signals pass through different types of capacitors, they encounter impedance. High-frequency metal-film capacitors have relatively low impedance, enabling them to transmit high-frequency signals more effectively. It’s just like when you’re listening to music—low-quality

The Key to Enhancing Electronic Device Performance: High-Frequency Metal Film Capacitors

The Key to Enhancing Electronic Device Performance: High-Frequency Metal-Film Capacitors In the design of modern electronic devices, the performance of these devices directly affects the user experience. Among the many factors that influence performance, high-frequency metal-film capacitors play an especially critical role. You might ask: Why do we specifically highlight this type of capacitor? The answer is simple—high-frequency metal-film capacitors not only enhance device stability but also significantly improve the efficiency of signal transmission. In this article, we’ll take a deep dive into the characteristics and advantages of high-frequency metal-film capacitors and explore how they elevate the overall performance of electronic devices. What Exactly Is a High-Frequency Metal-Film Capacitor? First, let’s take a closer look at what a high-frequency metal-film capacitor actually is. As the name suggests, this type of capacitor is made from metal-film materials and is specifically designed for high-frequency applications. Its unique structural features enable it to perform exceptionally well at high frequencies, effectively reducing signal distortion and attenuation. So why are high-frequency metal-film capacitors so outstanding under high-frequency conditions? The key lies in their low equivalent series resistance (ESR) and low equivalent series inductance (ESL). This means that energy loss during signal transmission is minimal, thereby greatly improving circuit efficiency. High-Frequency Metal-Film Capacitors vs. Traditional Capacitors Compared to traditional capacitors, high-frequency metal-film capacitors demonstrate...

Analysis of the Working Principle of High-Frequency Metal Film Capacitors

An Analysis of the Working Principle of High-Frequency Metal-Film Capacitors In modern electronic devices, high-frequency metal-film capacitors are an indispensable component. Thanks to their outstanding performance and stability, they are widely used in a variety of high-frequency circuits. So, how exactly does this type of capacitor work? Let’s dive deeper into the working principle of high-frequency metal-film capacitors. What Exactly Is a High-Frequency Metal-Film Capacitor? First, we need to clarify what a high-frequency metal-film capacitor is. Simply put, it’s a type of capacitor that uses a thin film material as its dielectric medium, typically consisting of metal electrodes and an insulating thin film. This design enables it to perform exceptionally well in high-frequency applications. Just as in a concert, the higher the frequency of a musical instrument, the more attention it tends to attract from the audience—similarly, high-frequency metal-film capacitors excel in delivering superior performance when handling high-frequency signals. How Does a High-Frequency Metal-Film Capacitor Work? So, how exactly does a high-frequency metal-film capacitor function? The underlying principle can actually be understood through a simple analogy. Imagine a capacitor as a water tank, and electric current as water flowing into that tank. The size of the tank determines how much water it can hold; similarly, the capacitance of a capacitor determines how much electric charge it can store. In a high-frequency metal-film capacitor, the metal electrodes are positioned on either side of the thin film.

How can the quality of surface-mount safety capacitors be effectively evaluated?

How Can You Effectively Assess the Quality of Chip Safety Capacitors? In electronic devices, chip safety capacitors play a crucial role. Have you ever wondered how to ensure that the chip safety capacitors you purchase are of high quality? In this article, we’ll explore several methods for evaluating their quality, helping you make more informed choices. Let’s Start by Gaining a Basic Understanding of Chip Safety Capacitors Before diving deeper, let’s take a moment to understand what chip safety capacitors are. Simply put, these capacitors are used in power electronics equipment and primarily serve to filter noise, stabilize voltage, and protect circuits from the effects of high voltages. They’re typically small and lightweight, making them ideal for surface-mount technology. However, there’s a wide variety of chip safety capacitors available on the market, with varying levels of quality. So, how can we effectively assess their quality? Let’s take a look at several key factors. 1. Check the Capacitor’s Specification Parameters First and foremost, the capacitor’s specification parameters are the fundamental basis for evaluating its quality. You need to pay attention to data such as the rated voltage, capacitance value, temperature coefficient, and voltage rating. For example, the higher the rated voltage, the stronger the capacitor’s ability to withstand voltage stress—just like when choosing a car, horsepower and safety standards are critical considerations. Similarly, the capacitor’s voltage rating and capacitance value must meet the requirements of your circuit design. 2.

A Deep Dive into the Production Process of Chip Safety Capacitors

Let’s delve deeper into the manufacturing process of surface-mount safety capacitors. In today’s electronic products, surface-mount safety capacitors play an indispensable role. From the smartphones, computers, and household appliances we use every day, almost none can do without them. Today, we’ll take a closer look at the production process of these surface-mount safety capacitors and explore how these tiny electronic components are made. What exactly is a surface-mount safety capacitor? Before we dive into the manufacturing process, let’s first clarify what a surface-mount safety capacitor is. Simply put, a surface-mount safety capacitor is an essential component used for electrical safety. It effectively isolates and filters high-frequency interference, protecting circuits from damage. Think of it like a window: it lets sunlight in while keeping out the wind and rain. Material Selection in the Production of Surface-Mount Safety Capacitors During the manufacturing of surface-mount safety capacitors, material selection is crucial. Commonly used materials include ceramics and polyester films. These materials not only need to exhibit excellent electrical performance but also must be able to withstand high temperatures and humid environments—just as when we choose clothes, we pay attention to both style and quality and comfort. An Overview of the Production Process Next, let’s break down the production process of surface-mount safety capacitors step by step. The entire process can be divided into several key stages:

The main difference between patch safety capacitors and conventional capacitors

The primary difference between surface-mount safety capacitors and traditional capacitors lies in the world of electronic components, where capacitors undoubtedly play a crucial role. Among the various types of capacitors, the distinction between surface-mount safety capacitors and traditional capacitors often leaves many engineers and enthusiasts puzzled. So, what exactly is a surface-mount safety capacitor? And how does it differ significantly from traditional capacitors? Today, let’s dive deep into this topic together. What is a surface-mount safety capacitor? First, let’s take a closer look at what a surface-mount safety capacitor is. As the name suggests, a surface-mount safety capacitor is a type of surface-mount capacitor commonly used to ensure the safety of electrical equipment. These capacitors are primarily employed in AC circuits, where they can effectively suppress electromagnetic interference (EMI) in power devices and guarantee that equipment continues to operate safely even in the event of a failure. You might wonder: Why is it called a “safety” capacitor? That’s because it meets stringent testing standards set by organizations such as UL and VDE, enabling it to function safely under high-voltage and high-temperature conditions. In contrast, traditional capacitors are typically used for general applications and may not have undergone such rigorous safety certifications. The key differences between surface-mount safety capacitors and traditional capacitors Next, let’s examine several key areas where surface-mount safety capacitors differ significantly from traditional capacitors.